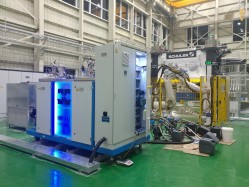

○ High-temperature and high-precision compression molding press can be available HP-IRTM, HP-CRTM and Wet Compression molding processes, and 10min or less process cycle is possible as preforming at part shape mold and high-speed mixing in mixing head of dosing unit.

○ As a method for HP-CRTM, it makes 0.2~1.0mm gap between molds and press for 100 bar on two-third position at injection process using mixing head, precise parallelism control is need for this process and continuous fiber –thermoplatic composite can be manufactured in 5 min.

○ At manufacturing the parallelism control between molds it should be needed to improve the dimensional accuracy of the parts that ensure the reliability required, by manufacturing a full scale composite part on mass production environment can be possibly

- material: carbon steel

- Temp. control unit : Up to (up to 130°C)

- Agitator: Magnetic coupling

○ Dosing unit for Resin & Hardener

- pump type: Axial piston pump

- Reculation feed pump: magnetic coupling

- Pipe heating tape: up to 150℃, 20m

○ Mixing head for HP-RTM

- output rate, MR=1/1 (g/s): 30~200

- Internal release agent module

- Mixing head piping

○ Mixing head for Wet-molding

- output rate, MR=1/1 (g/s): 30~200

- Internal release agent module

- Mixing head piping

- Fan: Flaat jet nozzle 20~200g/sec

○ Wet-molding for robot

- upper boom length: 3.2 m

- mechanical limits for axes 1, 2 and 3

- 6 free programmable moving axes