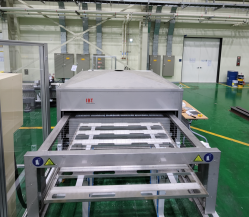

○ This equipment is used to preheat the thermoplastic/thermoset intermediate materials (prepreg, UD tape, etc.) and preforms (preforms) used for composite parts into molding equipment such as press (compression molding) and injection molding machines (overmolding, insert injection).

○ Heating System

- Temperature: 450°C

- Heated zone (WxD): 1500x1250 mm²

- 60 pieces of metal foil heater (by Krelus), 248x248 mm², 2.5 kW

- Layout of the heater in 2 modules:

* 1x module for heating from above

* 1x module for heating from below

- Subdivision of the modules into 7 zone

○ Design and mechanics

- Wire rope, stainless steel, 50 mm grid - spring-loaded

- Standard bearing height: 1000 mm above floor

- Device for pneumatically lifting the wire rope bearing for defined positioning of the needle gripper

- The oven stands on height-adjustable feet (possibility for lift and crane transport

- Temperature: 450°C

- Heated zone (WxD): 1500x1250 mm²

- 60 pieces of metal foil heater (by Krelus), 248x248 mm², 2.5 kW

- Layout of the heater in 2 modules:

* 1x module for heating from above

* 1x module for heating from below

- Subdivision of the modules into 7 zone

○ Design and mechanics

- Wire rope, stainless steel, 50 mm grid - spring-loaded

- Standard bearing height: 1000 mm above floor

- Device for pneumatically lifting the wire rope bearing for defined positioning of the needle gripper

- The oven stands on height-adjustable feet (possibility for lift and crane transport