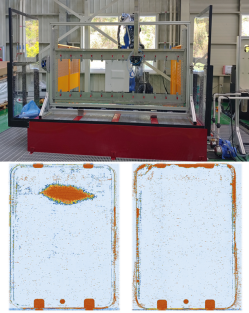

○ This equipment analyzes various defects (delamination, impact damage, overlap, wrinkle, misalignment/misorientation, undulation, void, etc.) of composite materials without breaking them.

○ Equipment to verify the effectiveness of the composite material process developed by deriving optimal material and process variables and minimizing internal defects

○ Type

- Waterjet Squirter

- Multiple curved (3D scan)

○Squirter type

- Squirter type: 6axis robot

- Water-jet system

- Scan area: 1.5m x 2.5m x 1.5m (L x W x H)

- Ultrasonic Probe, Pulser, Receiver

- 3D scaning software and analysis software

○ Applied Materials

- Pilot-scale automotive parts

- CFRP, GFRP, Sandwich structure(CFRP + Hard foam)

- Waterjet Squirter

- Multiple curved (3D scan)

○Squirter type

- Squirter type: 6axis robot

- Water-jet system

- Scan area: 1.5m x 2.5m x 1.5m (L x W x H)

- Ultrasonic Probe, Pulser, Receiver

- 3D scaning software and analysis software

○ Applied Materials

- Pilot-scale automotive parts

- CFRP, GFRP, Sandwich structure(CFRP + Hard foam)